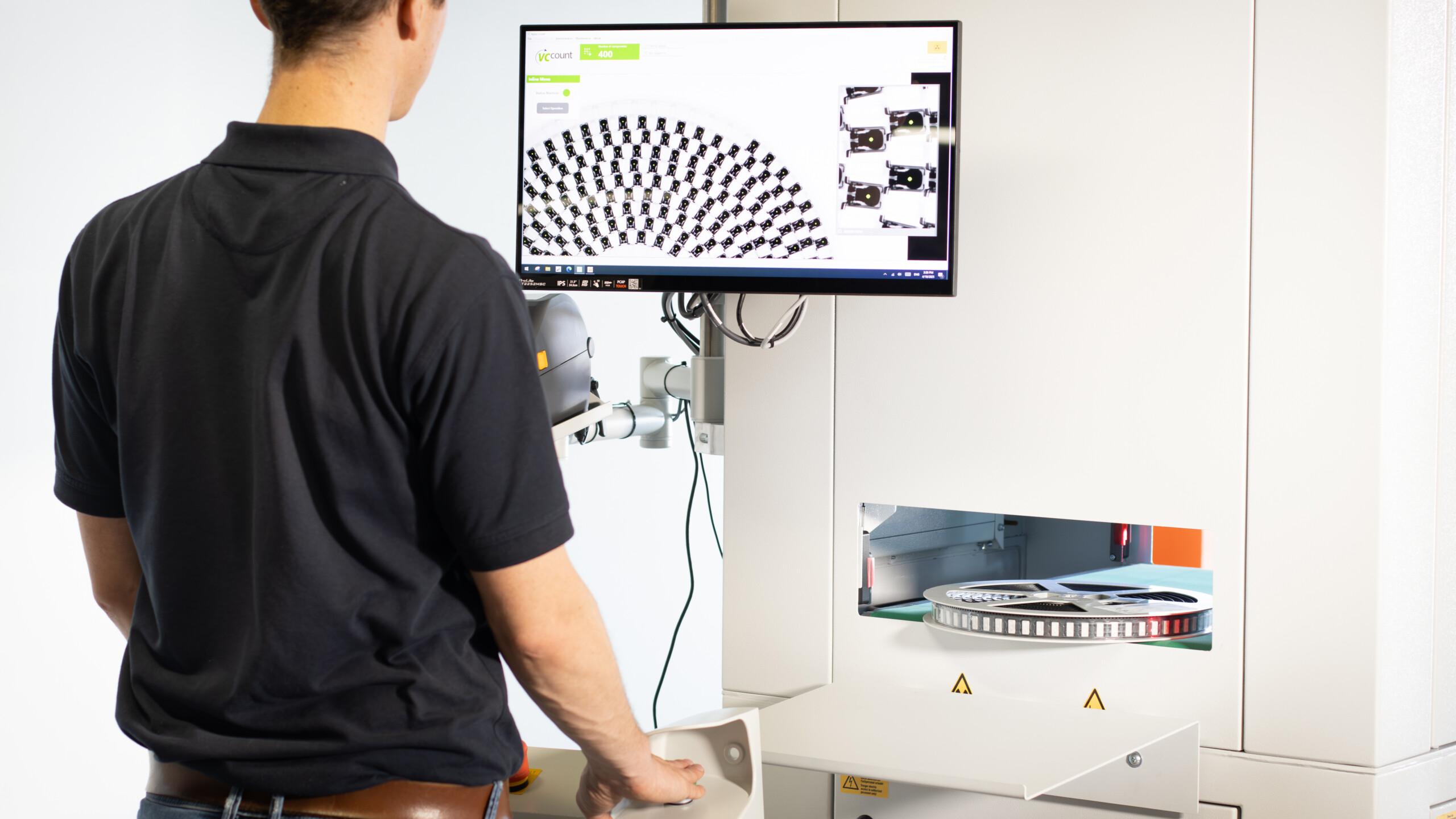

Inline counting for maximum efficiency

The XRHCount Inline is the perfect solution for anyone seeking maximum automation in their SMT production. The system can be fully integrated into your warehouse process and handles the contactless counting of component reels as they pass through, without any manual intervention.

Conveyor belts automatically load and unload the system, barcode recognition is integrated, 24/7 workflow.

Thanks to its scalable design, compatibility with Hermes or optionally Smema, and user-friendly software, XRHCount Inline is the next step towards the smart factory.

REDEFINED INLINE EFFICIENCY

INLINE WORKFLOW

INLINE WORKFLOW

Perfect fit for ASYS, Essegi, or other automated material logistics platforms.

REAL-TIME ERP CONNECTION

REAL-TIME ERP CONNECTION

Live inventory updates through smart connectivity with MES and ERP systems.

COMPACT FOOTPRINT

COMPACT FOOTPRINT

Designed to fit perfectly into modern SMT lines with minimal space requirements.

SCALABLE INVESTMENT

SCALABLE INVESTMENT

From pilot installations to full smart factory setups – grows with your needs.

24/7 OPERATION

24/7 OPERATION

Built for continuous operation in high throughput environments, day and night.

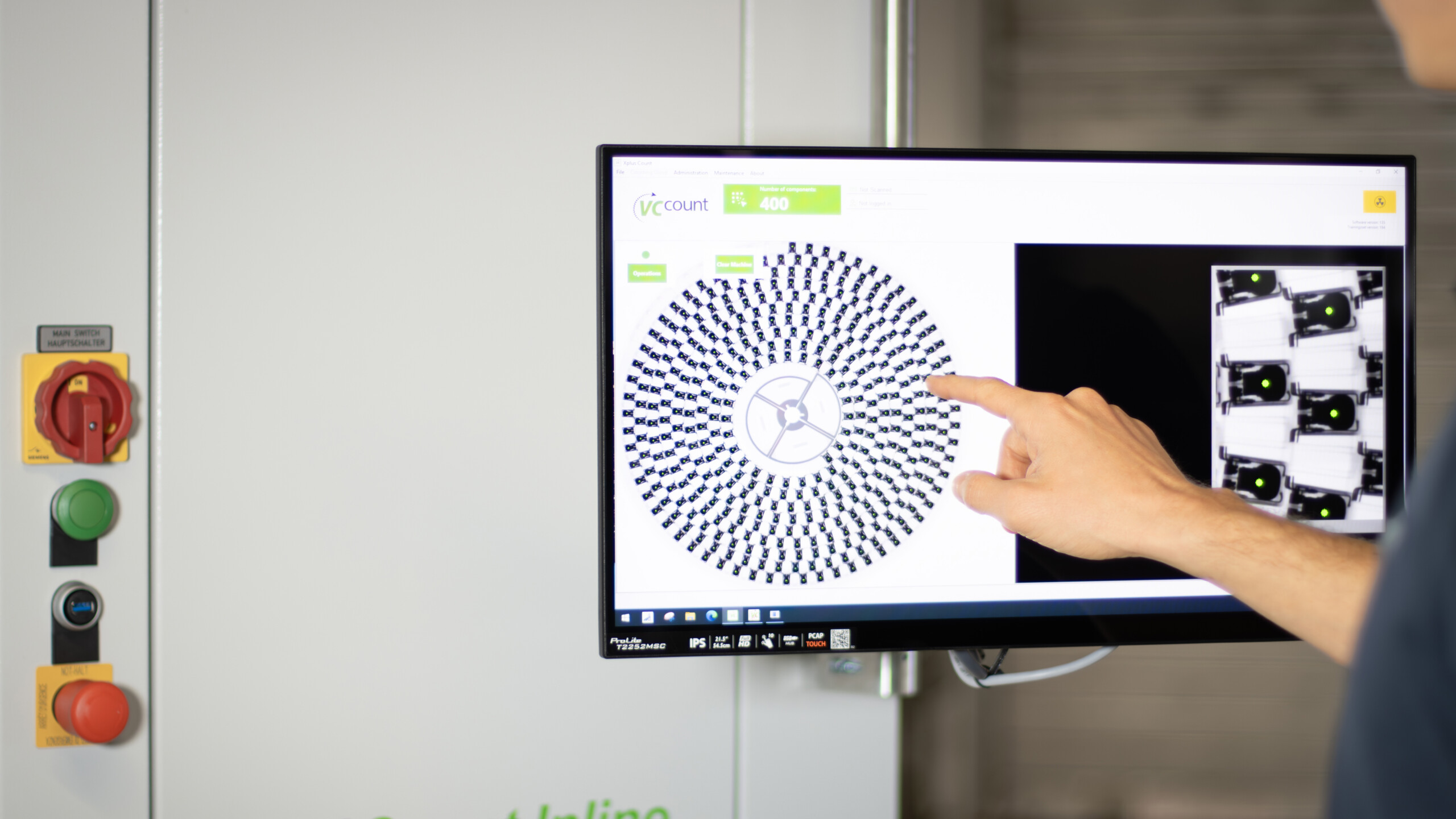

HIGHEST LEVEL OF AUTOMATION

HIGHEST LEVEL OF AUTOMATION

From loading to reel exit, no human interaction required.

CONTACT

Contact our team to connect XRHCount Inline

to your smart logistics system.

CALL US:

+49 (451) 290 286-0

SEND AN EMAIL:

info@visiconsult.de

Privacy Policy & Imprint

© 2025 VisiConsult X-ray Systems & Solutions GmbH