XRH Count – Smart Component Counting

Software Specification

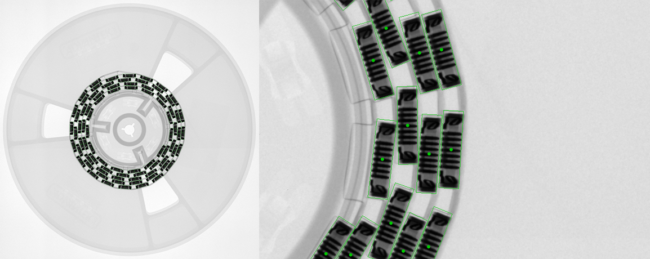

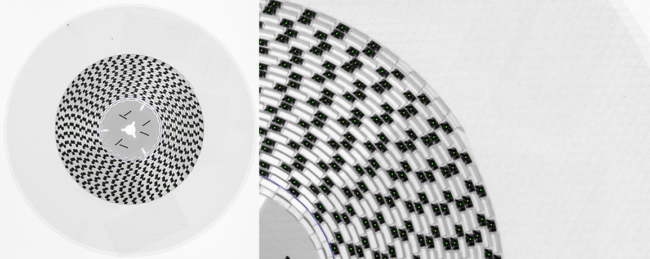

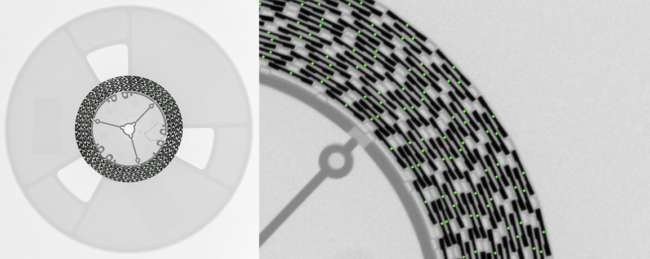

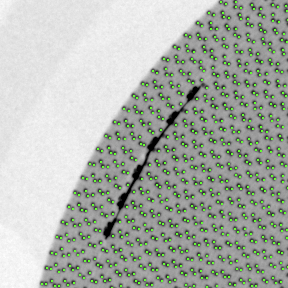

Splicing Detection

Metal splicing is common and widely used on SMD electronic industry, connecting two tapes. During X-ray counting process the image acquired shown the splicing visible as a dark spot.

The artificial intelligence of the XRHCount has a special algorithm to detect the metal splicing. When it is localized it gets excluded from the counting algorithm.

Excluding this identified, dark spot the result more reliable, since its poorly possible to determine if the metal pocket is empty or not. Assuming its not empty brings risks to your material inventory control.

compute-intensive applications such as AI, today’s high-performance and with this exclusive technique that’s directly manipulates the results and brings the most consistency on counting result set us apart!

The user can track the data of the reel.

- Number of splices on the reel

- Number of components before and after the splice

- Exclude the area of the splicing from the counting algorithm

- The amount of each area can be submitted to the ERP system

- The partial quantities can be printed on the new label

The splicing detection combined with the ASM Material Managers enables the functionality to update each unique ID between the splicings.

Regular Expressions (RegEx)

Human errors are prone to happen during data collection, a flawless process is mandatory to avoid wrong information assigned to the ERP/MRP.

Barcode scanning is an efficient and automated method that can save a substantial amount of efforts and time.

A powerful filter method RegEx tool is naturally required as the tracking and data gathering becomes essentially important, barcode scanner and ERP integration allows businesses to improve accuracy, productivity, and efficiency.

The RegEx tool monitors every barcode scanning step and validates it according to pre-defined rules.

Basic concept:

A regular expression, often called a “pattern”, is an expression used to specify a set of strings required for a particular purpose.

The admin can create and store rules according to the structure of the barcode data content. The operator is only able to perform the reading step, when the barcode matches to the pre-defined rules, the software provides allowance to proceed the counting process.

In case the barcode information does NOT match the specified rules, the system provides a warning message and blocks the process until an approved barcode is provided.

RegEx feature is an extra layer of protection between the counting process and your data quality to ERP system.

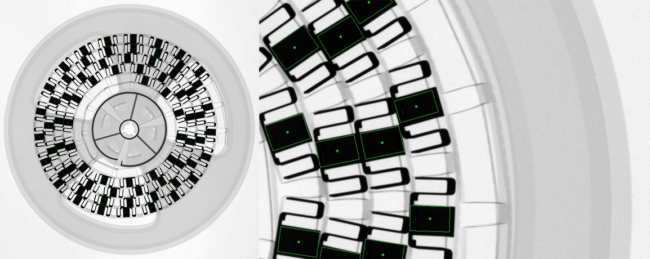

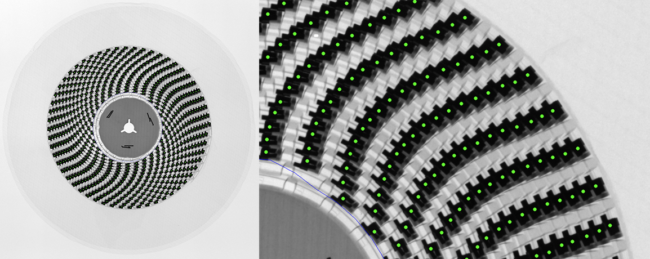

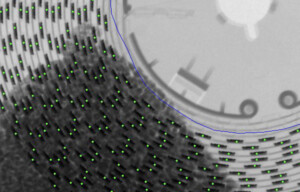

Counting of MSL bags with desiccant

MSL “Moisture Sensitivity Level” components and appropriate packaging for some semiconductors are mandatory in electronic industry.

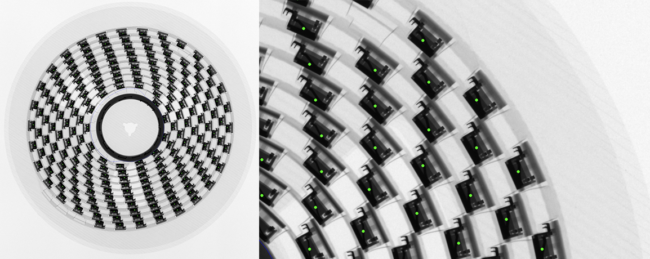

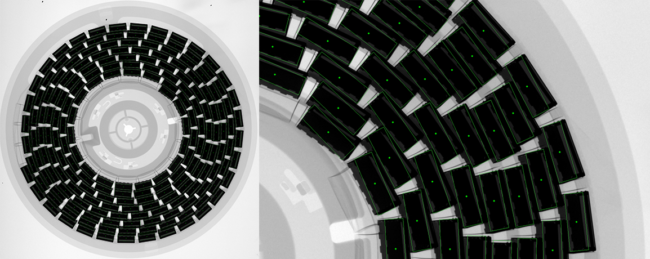

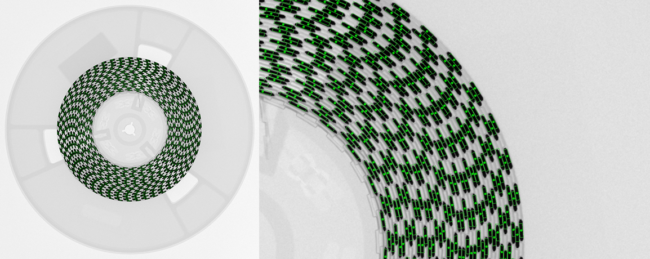

The current software version of the XRHCount makes it possible to count SMD-Reels even with foreign material “desiccant” over the top of the components.

The operator can put the whole bundle into the drawer (SMD Reel + antistatic bag and the desiccant), the artificial intelligence of the XRHCount has a special algorithm that will localize it and exclude the foreign material from the counting algorithm.

Operationally it is a tremendous advantage, because it’s not needed to open the antistatic bag to perform the counting process. It saves time and consequently money!

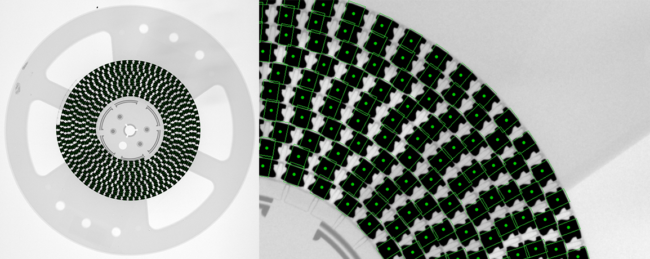

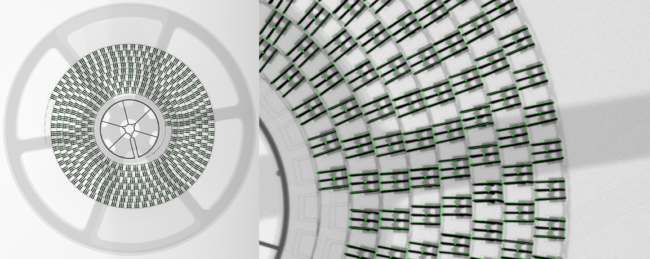

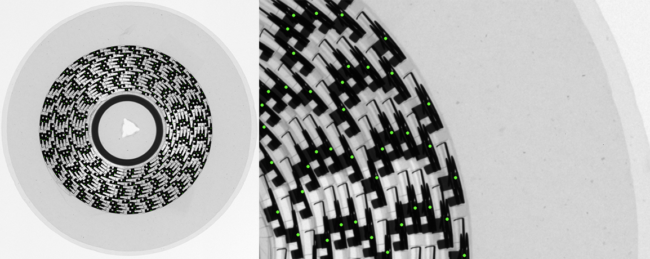

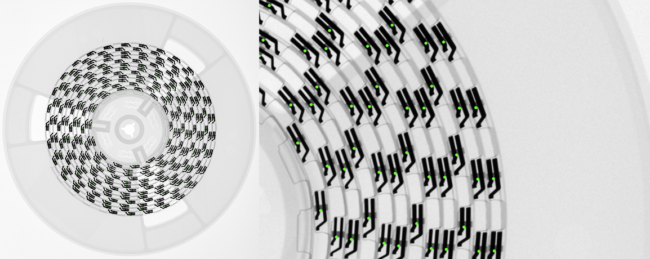

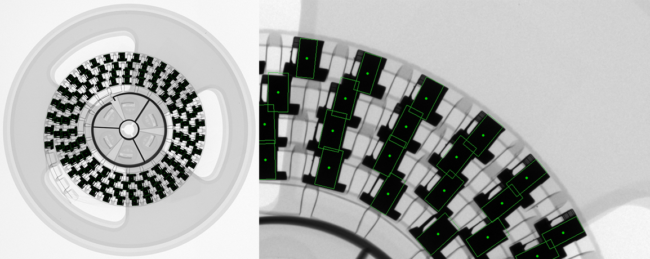

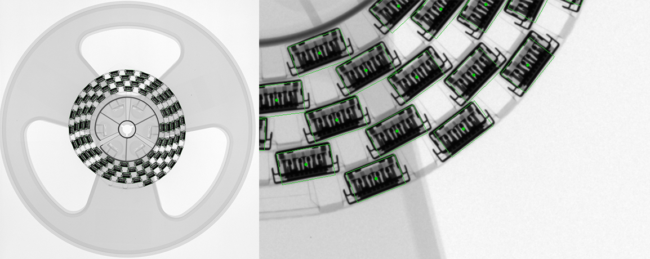

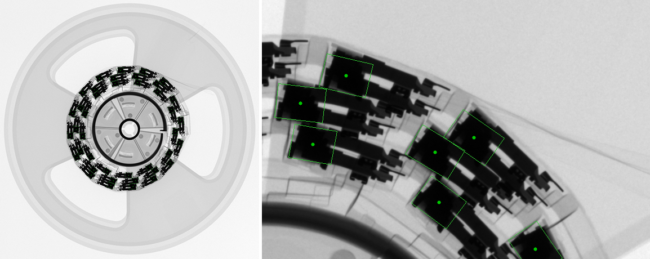

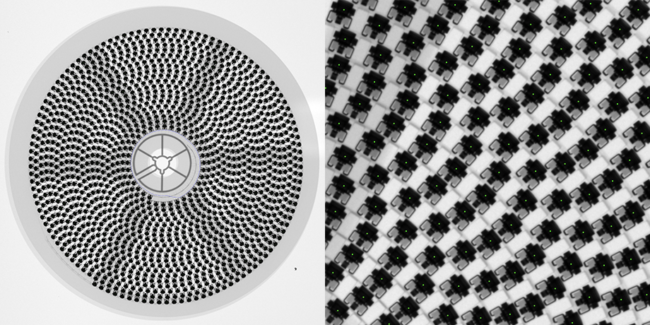

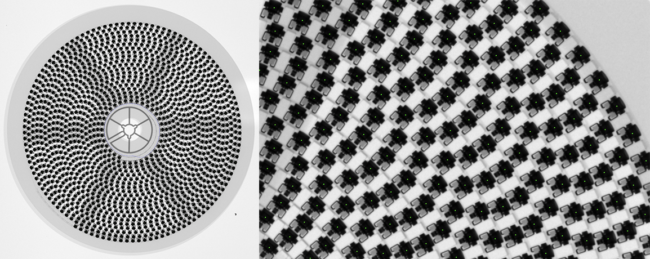

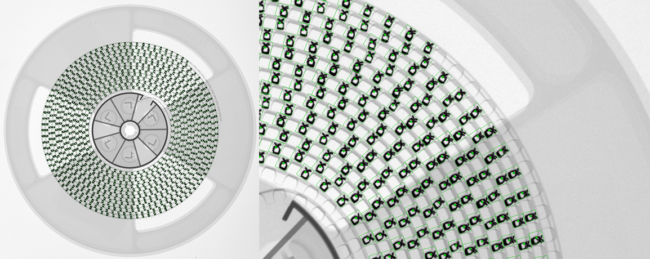

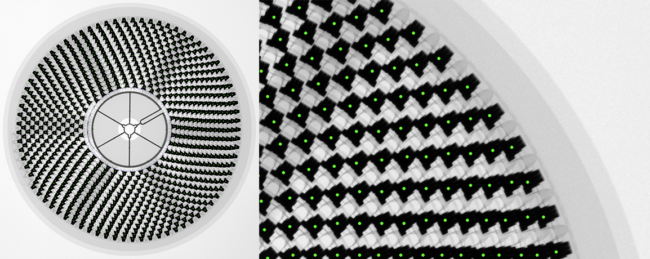

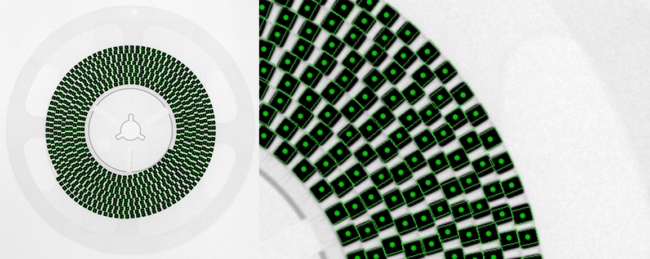

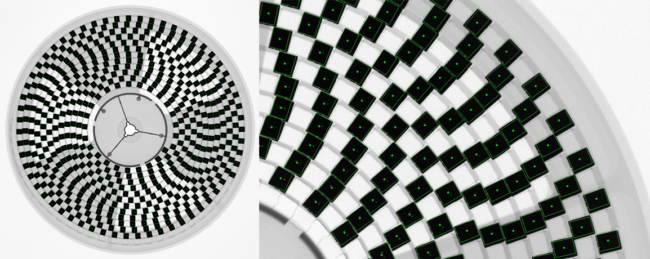

Recognition of odd shapes

XRHCount has nonstop software and algorithm development, dedicating long time period on new algorithms creation and providing ability to count tough forms even with overlapping of encapsulation.

Since the launching of the 1st system, VisiConsult has been actively working with data sharing of “real Images”. It means real field approach, gigabytes coming from all customer globally, this clever solution enhances our local database, based on learning experience of other users.

It reflects the actual database that knows and treats complex or irregular shape components. There are no limits for our image treatment software to provide most accurate count.

As known, there are a wide variety of shapes used in the SMT market: Chips, SMT connectors, IC’s, BGA and many others…

It is important when evaluating X-ray Counting systems to consider this. Do our algorithms handle a wide range of parts? Do the Artificial Intelligence operate the counting easily for complex or irregular components?

Statistic Suite

The Statistic- & Maintenance Suite fosters what has been called a “smart factory”.

The predictive information on the maintenance tab is a based solution for management problems of the system. It is an example of how big data analytics and advanced AI algorithms can help detect part failures via hidden correlations that otherwise would be impossible to find, hereby avoid failures before they happen.

The Statistic- & Maintenance Suite is supporting the local maintenance team for serving the management in an optimal way.

The maintenance area is displaying the condition of the system. To perform a preventive maintenance visit at the right time, the engineers can track different data. The key values are: X-ray tube hours, light barrier faults, emergencies, drawer cycles, start button pressed and software updates.

The Statics tab helps and displays easily the system utilization, the frequency can be sorted out per day, week, month or year of the system.

With this data, the ROI can easily calculate and the management can track system performance either operational performance.

System communicates and cooperates with real-time data that can be shared across organizational dashboard offering a competitive advantage in supply value chain!

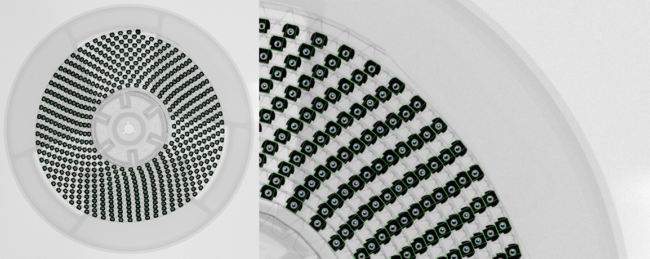

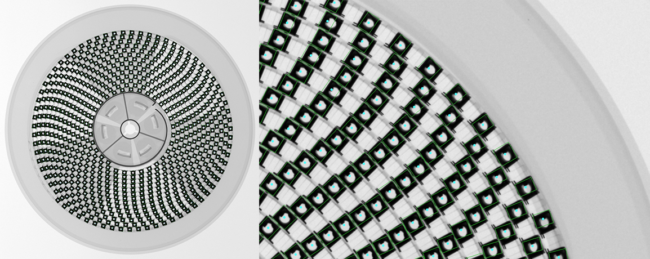

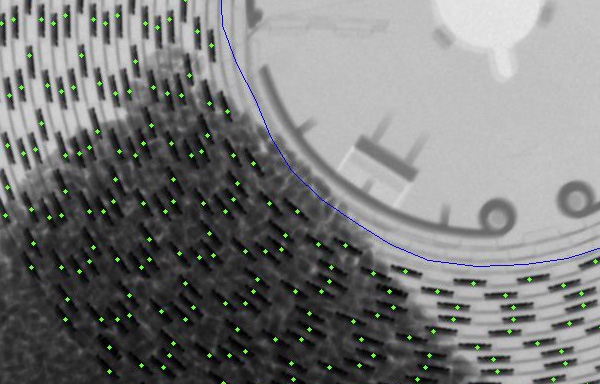

PCB

PCB inspection is an essential element in any electronics manufacturing process. The PCB inspection enables faults to be detected as soon after the manufacture process as possible. It is very important to check that solder joints on packages such as BGAs (Ball Grid Arrays) are being correctly soldered. The X-Ray system is able to look under the chips to view the solder joints. VisiConsult developed an application called XPlus Viewer, this is a separate analyzation tool to support on PCB inspection. This additional feature enables the user to inspect soldering points. A quick check-up can be made within a few seconds and the edited images can be saved as an .jpg for further investigations.

VisiConsult developed an application called XPlus Viewer, this is a separate analyzation tool to support on PCB inspection. This additional feature enables the user to inspect soldering points. A quick check-up can be made within a few seconds and the edited images can be saved as an .jpg for further investigations.

New Software Features

As soon as the XRHCount arrives at a facility it is ready to use. The Plug and Play model is based on the basic premise that system teaching is not required because it already has a globally proven database stored locally. This results in no lost time to get the counting started.

The newest software version has a very intuitive user interface that was developed in correspondence to the customer’s request of a touch screen.

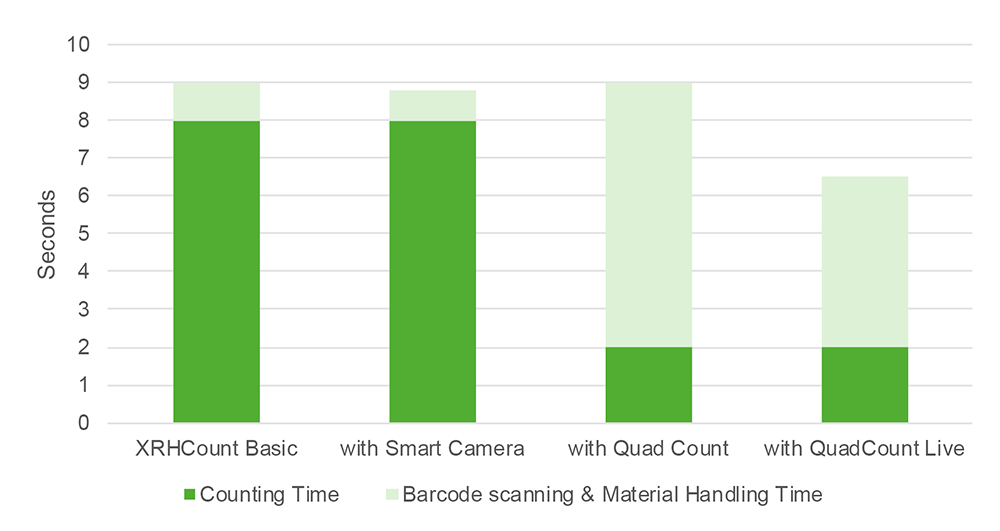

The cycle time is optimized via improved hardware and software. The new generation of the system is up to 20% faster and counts within 8.5 seconds per reel, and the Quad Count just needs 2 seconds per reel. The table on the back shows the timings of the counting process: Drawer loading + component analysis + unloading.

For smart industries the system is ready for robots, and the free Connectivity Suite ensures an easy integration into the customer’s existing systems – now real-time data can be integrated to the facility’s ERP system or even be exported into a file based on usual industrial formats like XML or CSV.

Mechanically, the design of the drawer was optimized by a new concept using linear guides and lower weight, and maintenance time is reduced by implementing more access points for the service technician.