XRHCount – FAST, INTUITIVE, READY TO USE

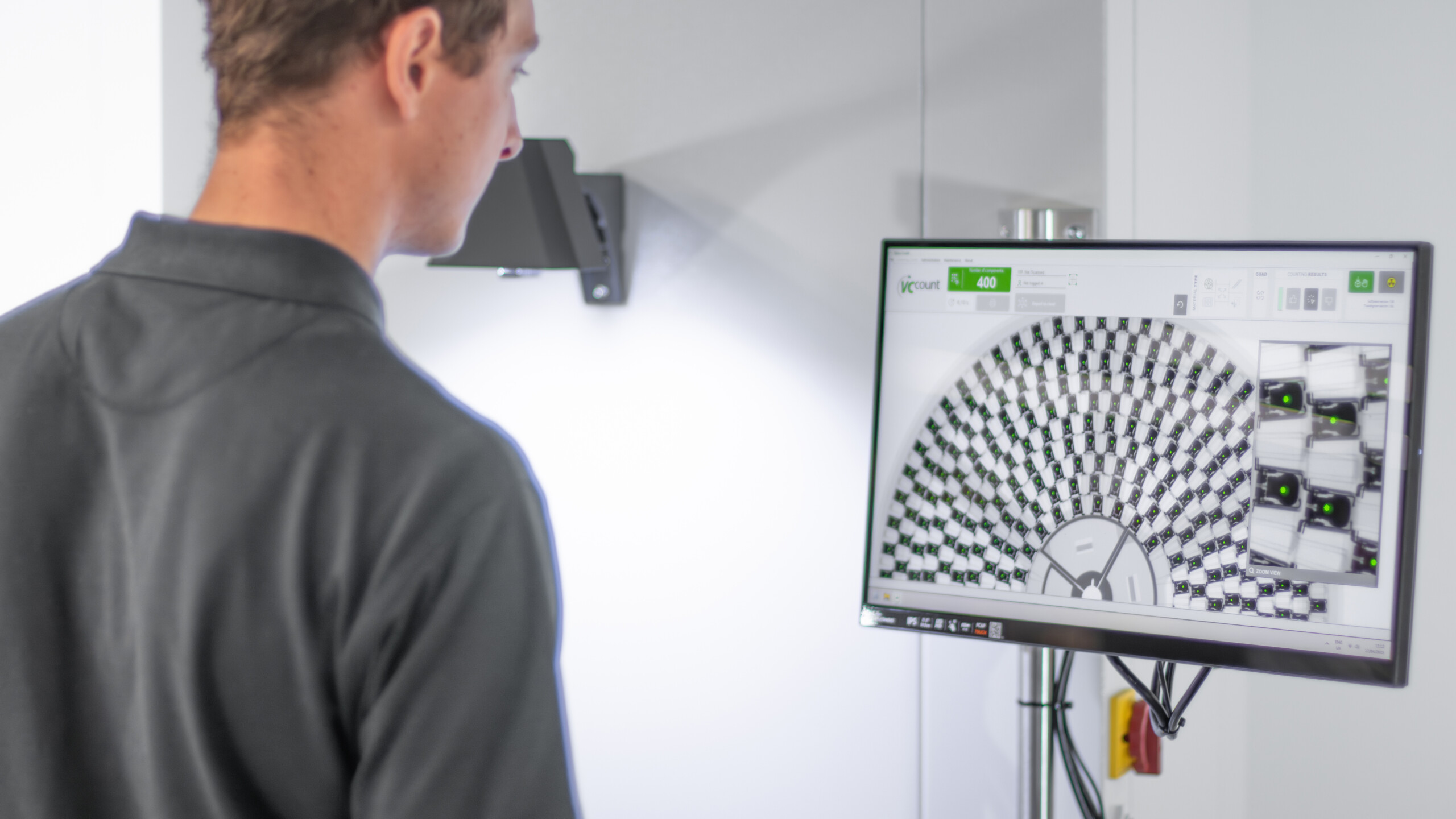

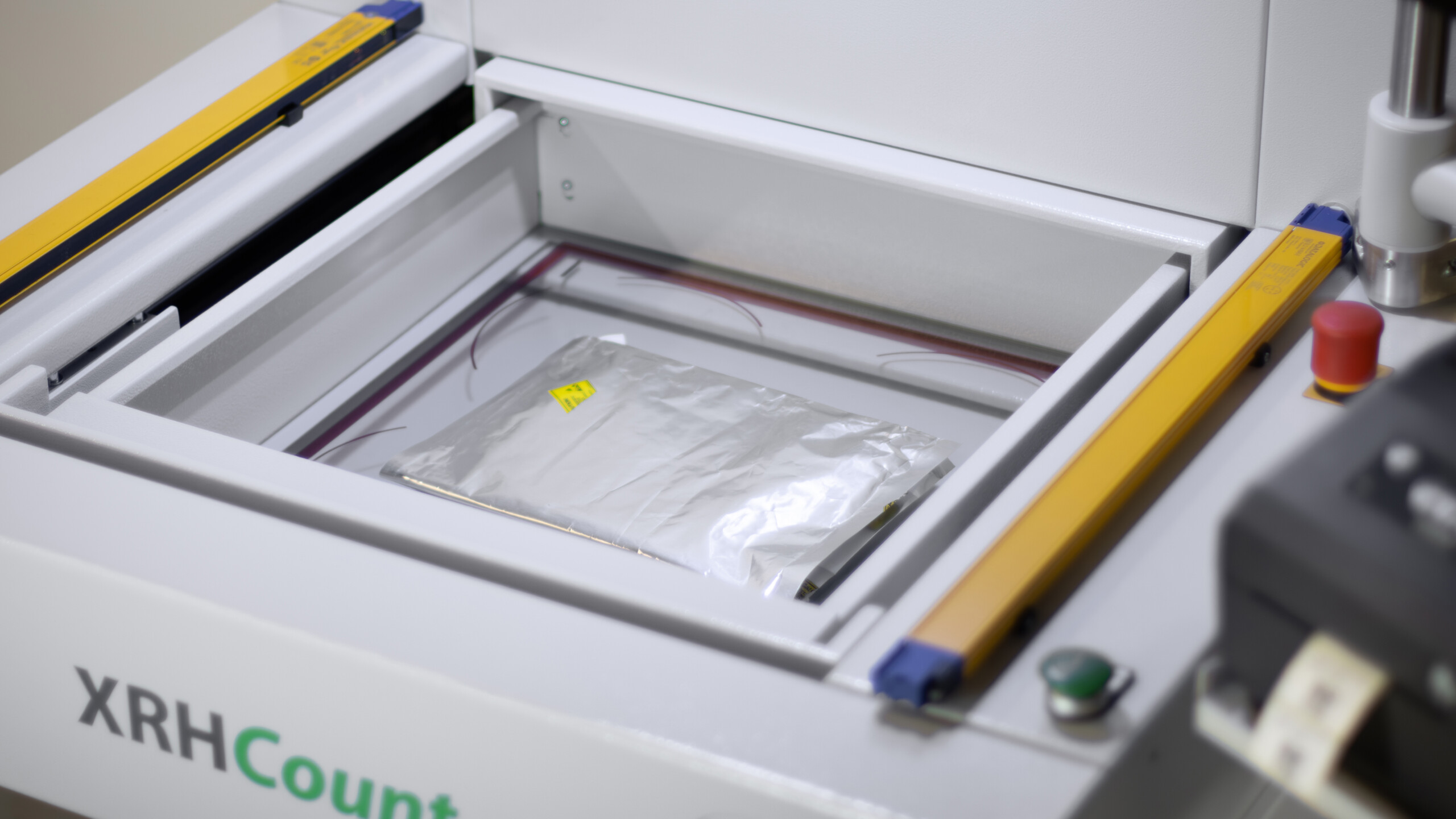

The XRHCount offline system offers a compact and ready-to-use solution for the contactless counting of SMD components. Thanks to the plug-and-play principle, intuitive touchscreen interface, and integrated smart camera, the system is up and running in no time, and requires virtually no training..

With a cycle time of just 7 seconds per reel (or 2 seconds with QuadCount), XRHCount ensures maximum efficiency in incoming goods or warehouse management. The free Connectivity Suite enables seamless integration into existing ERP systems – for transparent processes and perfect traceability.

WHAT SETS XRHCount APART

FAST CYCLE TIME

FAST CYCLE TIME

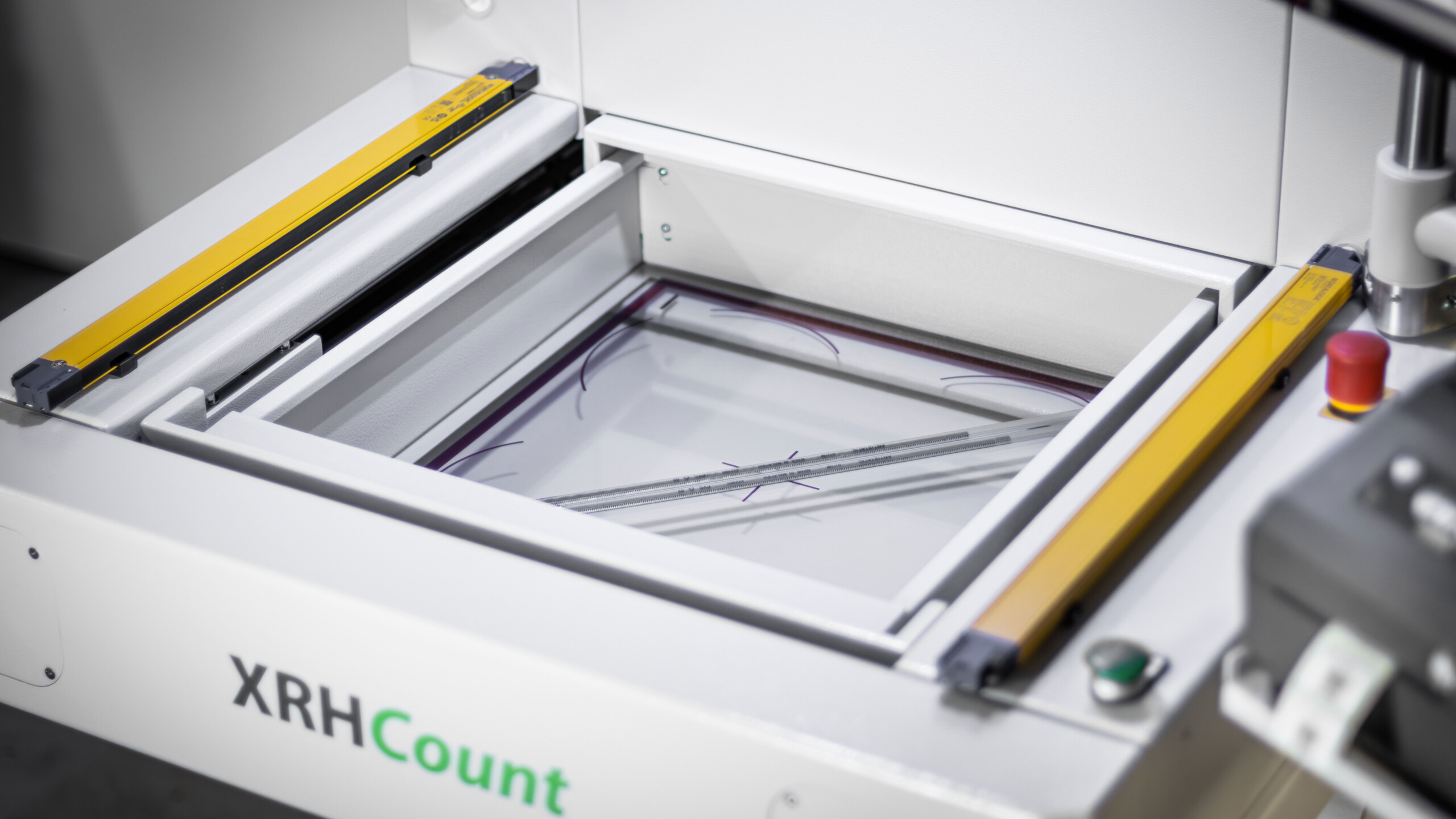

Count an entire reel in just 7 seconds without unpacking or manual setup.

INTUITIVE OPERATION

INTUITIVE OPERATION

User-friendly touchscreen interface requires no training or prior knowledge

QUAD COUNT TECHNOLOGY

QUAD COUNT TECHNOLOGY

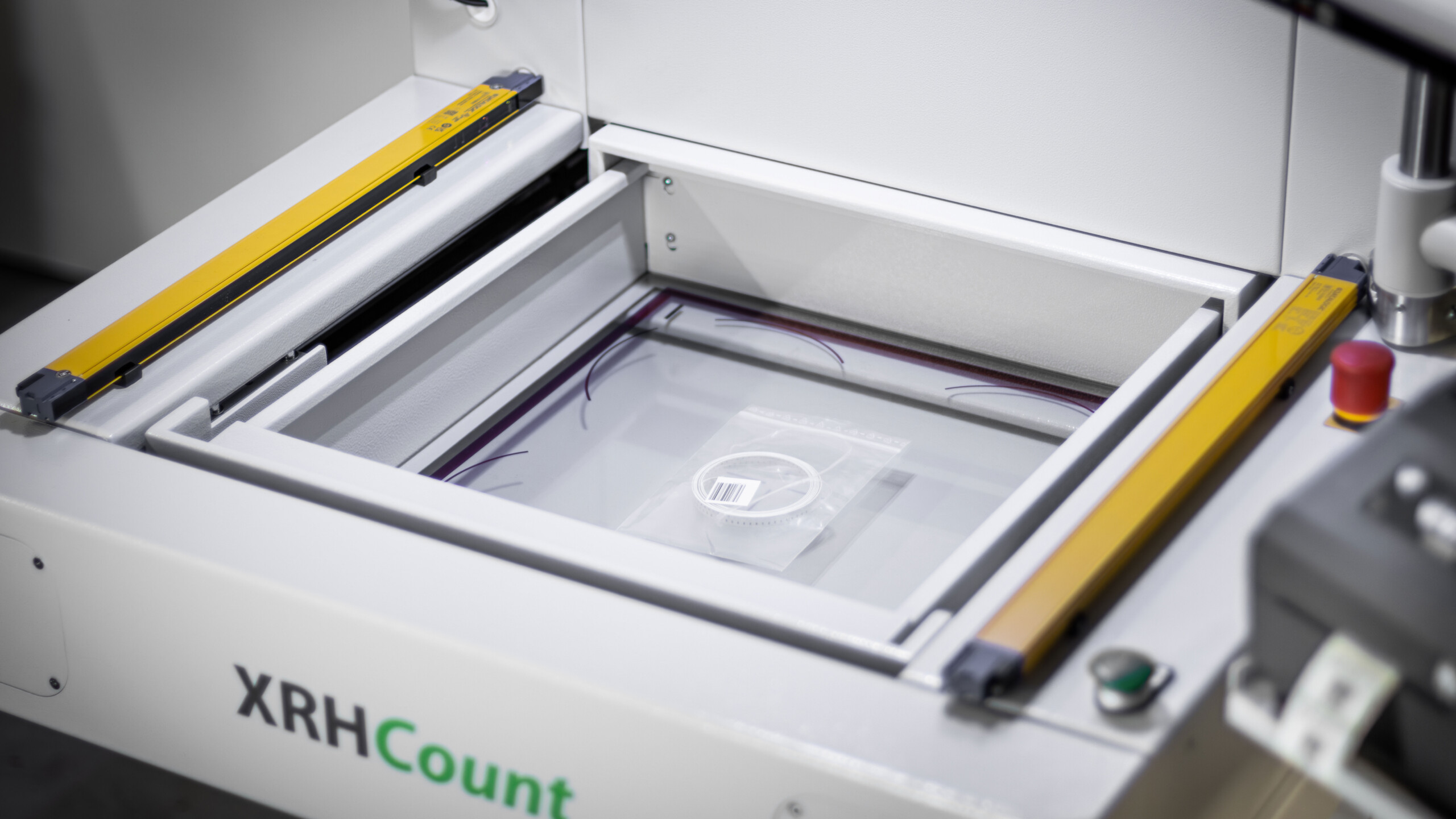

Count up to 4 reels simultaneously thanks to our area scan camera

COMPACT FOOTPRINT

COMPACT FOOTPRINT

Designed to fit into tight production spaces with minimal installation effort.

PLUG & PLAY INSTALLATION

PLUG & PLAY INSTALLATION

Delivered ready-to-use with no system training or setup effort required.

COUNTING CLOUD

COUNTING CLOUD

Large reference database – no manual training required

20 MP AREA SCANNER

20 MP AREA SCANNER

Automated barcode recognition using a high-resolution 20 megapixel area scanner.

CONNECTIVITY SUITE INCLUDED

CONNECTIVITY SUITE INCLUDED

Enjoy seamless ERP integration with no additional programming – your data flows instantly to where it’s needed.

MADE IN GERMANY

MADE IN GERMANY

Engineered, manufactured, and tested in Germany.

SEAMLESS DATA INTEGRATION

With the included Connectivity Suite, your counting results can be exported instantly to your ERP, MES or inventory system, with no extra installation or configuration required.

FLEXIBLE COUNTING MODES

Whether reels, sticks, or trays, XRHCount handles a wide range of SMD types. Explore our six specialized counting modes below.

CONTACT

Ready to get started? Contact our team for a

personal consultation or implementation support

CALL US:

+49 (451) 290 286-0

SEND AN EMAIL:

info@visiconsult.de

Privacy Policy & Imprint

© 2025 VisiConsult X-ray Systems & Solutions GmbH