WHY COMPONENT COUNTING IS A CRITICAL FACTOR

Any error in your component count can lead to production delays, material loss and increased costs. If components are missing or counted incorrectly, there is a risk of:

- production stoppages due to unexpected stock shortages

- high manual effort due to re-entry or re-ordering

- overstocking, which ties up capital and takes up additional space.

Manual counting methods are time-consuming and prone to error, which is why companies are increasingly turning to automated component counting. X-ray counting, in particular, has proven to be the most precise and efficient method.

X-RAY COMPONENT COUNTING WITH VCCOUNT –

THE FASTEST AND MOST PRECISE SOLUTION

THE FASTEST AND MOST PRECISE SOLUTION

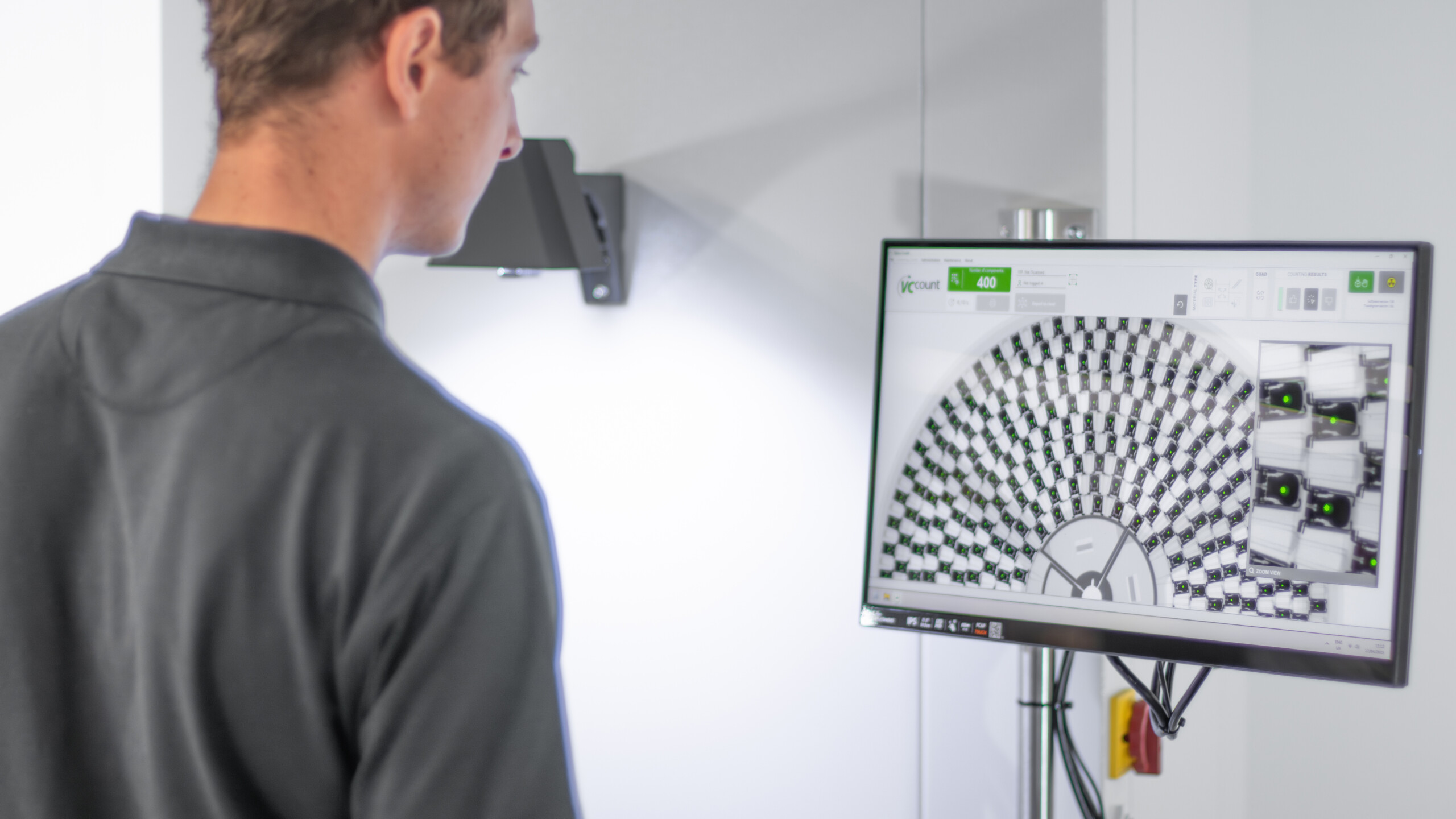

HOW DOES X-RAY COUNTING WORK?

1 Load

Insert the reel into the drawer – in packaging, no unrolling required.

2 Press the button

The drawer closes automatically, and with the touch of a button, the systems count the exact quantity.

3 Count

Component count, barcode, and reel information are displayed on screen.

4 Unload

Unload the reel, results are exported to ERP, printed, or saved – fully traceable.

Your optimal process for error-free component counting with a plug & play system that is ready to use immediately!

Reels, trays, cut tapes, and sticks can be counted directly in the original packaging, without unpacking or unrolling

The precise quantity is determined within seconds, perfect for fast production processes. The XRHCount delivers results in a cycle time of 7 sec. per reel.

Yes! Thanks to the included Connectivity Suite, the connection to your system is seamless.

Yes! VCcount works with reputable partners in this area, and a scalable investment with a step-by-step increase in automation is also possible.

The training required is very minimal, and the system is very easy to use. After a short introduction, employees can start recording the inventory immediately.

CONTACT

Ready to transform your SMD inventory?

We’ll help you choose the perfect setup for your needs.

CALL US:

+49 (451) 290 286-0

SEND AN EMAIL:

info@visiconsult.de

Privacy Policy & Imprint

© 2025 VisiConsult X-ray Systems & Solutions GmbH